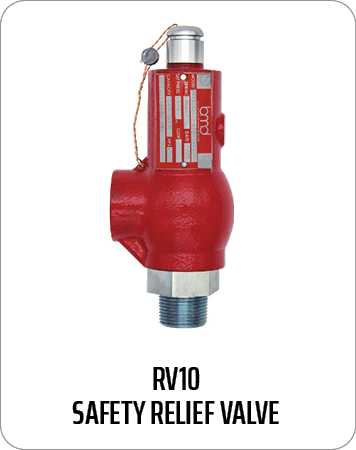

RV10

Safety Relief Valve

The RV10 safety relief valves from Beaumont Manufacturing and Distribution are precision-built for overpressure protection of production equipment. With all-star features like our non-rising stem and soft-seat design help for longevity, efficiency, and reliability in the field.

- Well-suited for overpressure protection of production equipment

- Non-rising stem and soft-seat design ensure long lasting set pressure repeatability

- Bubble-tight shutoff thanks to our non-rising stem and soft-seat design

- ASME certified for gas service

- Manufactured in accordance with the ASME BPVC, capacity tested and certified by the National Board

- Meets the requirements of Section VIII, Div. 1 of the ASME Code

- Orifice sizes D-Q available in a wide variety of inlet/outlet sizes and connection combinations

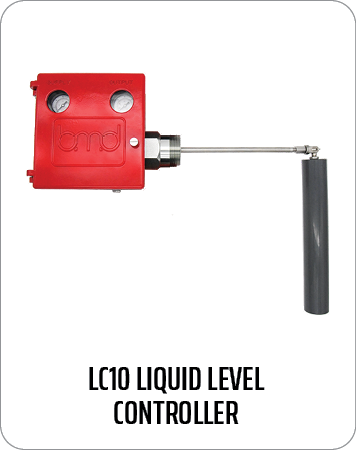

| Specifications for Standard LC10 | |

|---|---|

| Sizes | 2", 3", 4" |

| Connections | Female NPT, Flanged |

| Body Type | Globe, Angle |

| Trim Characteristic | Quick Open |

| Trim Size | 2” Body Size: 2”, 1 1/2”, 1”; 3” Body Size: 3”, 2”, 1”; 4” Body Size: 4”, 3”, 2”, 1” |

| Trim Type | Balanced |

| Pressure Rating | 500 psi - NPT Ends 250 psi - Flanged Ends |

| Temperature Rating | -20º F to 400º F (-29º C to 204º C) |

| Materials for Standard LC10 | |

|---|---|

| Body | Ductile Iron |

| Bonnet | Ductile Iron |

| Seat | Stainless Steel |

| Stem | Stainless Steel |

| Shaft | Stainless Steel |

| Bolting | A193 B7 (Standard Materials are NACE Compatible) |

Find the right valve for your project with our custom builder

Contact sales to start your purchase for your next project

Related Articles & Training

By Website Editor

•

July 11, 2025

How to Maintain & Troubleshoot Relief Valves for Long-Term Performance Relief valves serve as essential safety equipment in oil and gas operations, regulating system pressures to safe levels while preventing destructive system failures. They operate as safety devices for pipelines, separators, and storage tanks throughout upstream and midstream oil and gas systems. BMD produces spring-loaded pressure relief valves that fulfill the highest requirements for durability, corrosion resistance, and reliability. However, even the most durable valves require scheduled maintenance and prompt troubleshooting to achieve optimal performance. Failing to maintain equipment properly leads to operational downtime, increased safety risks, and costly repair expenses. The following article provides instruction for relief valve maintenance and troubleshooting to ensure BMD valves operate safely and efficiently throughout their extended lifespan. Understanding BMD Relief Valves BMD relief valves are reliable and long-lasting. They can handle high-pressure systems, protecting against overpressure situations that could otherwise compromise the integrity of pipelines, storage tanks, and other critical equipment. BMD offers spring-loaded pressure relief valves that serve multiple applications across the oil and gas sector. The valves are in pipelines, separators, and storage tanks, where they protect equipment from overpressure. BMD valves surpass American design standards to deliver peak performance in demanding operational conditions. Common features include: Corrosion Resistance: BMD relief valves are designed to withstand corrosive environments commonly found in oil and gas operations, ensuring durability and a longer service life. Spring-Loaded Design: These valves provide reliable pressure relief by automatically opening when the system pressure exceeds the preset limit. American-Made Durability: Designed and manufactured in the U.S., BMD relief valves offer a high level of precision, performance, and safety. When properly installed and maintained, these valves can significantly improve the safety and efficiency of your oil and gas systems. Understanding their design and function is key to performing effective maintenance and troubleshooting. Why Relief Valve Maintenance is Critical Relief valves protect oil and gas operations by preventing overpressure, which can stop leaks, prevent equipment damage, and prevent catastrophic failures. The relief valves require regular maintenance to maintain their optimal operational state. Poorly maintained relief valves can cause various issues, such as: Worn seals or improper valve seating can result in leaks that compromise system pressure and cause safety hazards. If a valve opens too frequently or at the wrong pressure, it can cause unnecessary pressure drops that disrupt operations. Accumulation of debris or corrosion inside the valve can block the flow path, reducing the valve’s effectiveness. Regular inspection and maintenance can help detect and resolve these issues before they escalate. BMD recommends inspecting relief valves regularly based on operational conditions, including pressure cycles and environmental factors. Follow the manufacturer’s guidelines for maintenance intervals to ensure that valves perform reliably over time. Relief Valve Standards & Maintenance Recommendations BMD manufactures safety relief valves under Section XIII of the ASME code. To maintain compliance and performance, all relief valves need to be sent to a qualified VR shop for reset and recertification—this process cannot be performed by the end user. In addition, BMD strongly recommends that customers have a maintenance program in place that includes annual re-certification by a National Board certified shop holding a VR stamp to ensure safety, reliability, and regulatory compliance. Relief Valve Troubleshooting: Common Issues and Fixes Regular maintenance does not prevent relief valves from developing problems. The following section outlines typical problems together with specific troubleshooting procedures for BMD valves. The valve fails to open at its specified pressure setting. Possible Causes: Incorrect valve settings or blockage. Troubleshooting: The spring condition should be checked for wear while verifying that the valve operates at its designated pressure setting. The valve components need cleaning to remove any blockages that might exist. The valve operates at higher frequencies than expected or before reaching the set pressure. Possible Causes: Fluctuating process pressure, debris under the seat, or incorrect settings. Troubleshooting: The valve seat should be inspected for debris while verifying that the pressure settings match the specifications. The necessary adjustments or replacements should be made to the components. The valve develops leaks after its activation. Possible Causes: Seat wear, seal damage, or improper reassembly. Troubleshooting: The internal components need replacement or reseating according to the situation. All parts need correct alignment during reassembly to stop leaks from occurring. Audible chattering or vibrations. Possible Causes: Back pressure, poor mounting, or improper valve sizing. Troubleshooting: Check both the mounting and installation procedures and backpressure conditions. BMD provides installation guidelines which help users select appropriate valves and determine correct flow sizes. Long-Term Performance Tips for BMD Relief Valves The following best practices will help you achieve long-term performance: Create a maintenance schedule that considers operating conditions and manufacturer recommendations. Maintain detailed documentation of all maintenance work, inspection results, and replacement records. Technicians should receive BMD-specific maintenance training to perform proper care of the equipment. The use of OEM parts for all repair and rebuild operations will preserve both performance and reliability. Send the valve to BMD for factory service or certified testing when issues persist or when the valve exhibits significant signs of wear. Conclusion The oil and gas industry requires regular maintenance and accurate troubleshooting of relief valves to ensure safe and reliable operations. BMD relief valves are built to withstand demanding conditions, but their long-term performance depends on regular maintenance. The maintenance and troubleshooting guidelines in this guide will help you maintain relief valve reliability, which leads to better system safety and compliance, along with operational efficiency. For further assistance with OEM parts or technical support, contact BMD.

By satha

•

April 11, 2025

Oil and gas production involves managing large volumes of hydrocarbon fluids, often under high temperatures and pressures. Due to this, production systems—composed of wells, wellheads, pipelines, vessels, pumps, and compressors—must be equipped with robust protection mechanisms to prevent failures caused by overpressure. Among these, relief valves are the most vital components for overpressure protection within a pressurized system. Their importance is such that they are commonly referred to in the industry as “Ultimate Safeguards.” Relief valves safeguard oil and gas production systems by preventing ruptures caused by excessive pressure. They help shield personnel, the environment, and infrastructure from catastrophic outcomes that can be caused by uncontrolled hydrocarbon release. They contribute to operational efficiency by ensuring that pressure excursions are safely handled while preserving the integrity of production systems. Beaumont Manufacturing and Distribution Company (BMD) is a trusted relief valve supplier to the oil and gas industry, with a range of safety relief valves that are well-suited for overpressure protection of production equipment. This guide will help you to select the correct relief valves for your oil and gas applications. It covers the working principles, key selection criteria, regulatory aspects, proper installation, and maintenance practices. Understanding Relief Valves in Oil and Gas Applications A relief valve is a pressure control device that opens to relieve excess pressure and recloses once conditions normalize. A conventional relief valve has an inlet nozzle, a movable disc, and a spring that sets the pressure threshold. By balancing forces, fluid pressure exceeding the spring’s set limit opens the valve, safely releasing excess fluid. When pressure falls, the spring reseats the disc, closing the valve. This mechanism prevents overpressure and ensures safe system operation. BMD’s RV10 relief valves are precision-built for overpressure protection of production equipment and designed for longevity, efficiency, and reliability in the field. RV10 relief valves are manufactured in accordance with the ASME BPVC, and capacity tested and certified by the National Board. Relief valves in oil and gas operations prevent overpressure in equipment like separators, compressors, and pipelines. These situations could arise, for example, due to blockages, surges, thermal expansion, or control failures. By opening at preset pressure levels, relief valves safely release excess fluid into a relief header system, protecting equipment from rupture and ensuring operational safety. Key Factors to Consider When Selecting a Relief Valve Choosing the right relief valve involves evaluating several key factors to match the valve with system requirements effectively. Some key factors are: Operating Pressure and Set Pressure: To avoid leakage due to simmering action when the maximum operating pressure approaches the relief valve set pressure, sufficient margin must be provided between the two. For most applications the operating pressure should be no more than 90% of the set pressure. If vibration is present or pressure surges are expected then it should be even lower. Flow Capacity (Sizing Considerations): Relief valves must be sized for the worst-case relieving scenario (governing case). When sizing a relief valve the required capacity, set pressure, relieving temperature, and fluid properties should be specified in order to properly select the correct size valve. In some cases multiple valves may be used in parallel. Flow capacity calculations are performed per API and ASME codes. Type of Fluid/Gas Being Processed: The physical and chemical properties of the fluid being handled impact the size of relief valve needed, as well as choice of materials. All operating and relieving scenarios must be considered while evaluating the fluid properties. For example, crude oil may be light or viscous, there may be fouling asphaltenes or waxy substances. Natural gas may contain corrosive acid components. Gas with free water may form hydrates. Temperature and Environmental Conditions: Relief valves must retain their integrity at conditions to which they are constantly exposed as well as at relieving conditions. High temperatures need heat-resistant components, while cryogenic systems demand materials suited to extreme cold. Environmental factors such as ambient temperature, humidity, precipitation, desert conditions, and offshore service, will affect the choice of materials. Material Compatibility: It must be ensured that the materials used in the relief valve are compatible with the process fluid at all operating and relieving conditions. For example, relieving scenarios may be at high temperatures and pressures whereas operating conditions may be mild. Corrosion resistance is essential. BMD relief valves are manufactured using different materials as shown in Figure 1. BMD Relief Valves and Their Applications Overpressure risks in the oil and gas industry encompass a wide range of operating conditions. BMD’s RV10 series of spring-loaded relief valves span a set-pressure range of 15-3000 psi and temperature range of -50 oF-400 o F. Available in different models to suit varying requirements, RV10 safety relief valves are an ideal choice for overpressure protection of compressors, scrubbers, separators, pipelines and other systems where overpressure protection may be required. BMD’s RV10 Relief Valves incorporate a non-rising stem design that gives the disk full guidance, while opening and closing. This is coupled with a soft seat design that ensures long lasting set pressure repeatability and bubble tight shut-off. The shorter stem makes the valve compact and ideal for tight spaces. The RV10 is ASME-certified for gas and liquid service and is available in NPT and flanged connections. The flanged relief valve sizes meet API 526 dimensions. The RV10 is manufactured in accordance with the ASME Boiler and Pressure Vessel Code, capacity tested and certified by the National Board, and meets the requirements of Sec on VIII, Division 1 of the ASME Code. Regulatory Compliance and Industry Standards for Relief Valves Relief valve design and operation are subject to rigorous regulations established by various organizations. For oil and gas installations within the USA, the most important national standards are as follows: API Standard 520, Part 1 Sizing, Selection, and Installation of Pressure-relieving Devices Part I—Sizing and Selection. API Standard 520 Part II, Sizing, Selection, and Installation of Pressure-relieving Devices Part II—Installation. API Standard 521, Pressure-relieving and Depressuring Systems. API Standard 526, Flanged Steel Pressure-relief Valves. API Standard 527: Pressure Relief Valve Seat Tightness. ASME Boiler and Pressure Vessel Code (BPVC). Regular inspections, testing, and documentation are critical for demonstrating compliance during audits. Best Practices for Installation and Maintenance Relief valves should always be installed and maintained according to manufacturer guidelines and industry standards. Position the valve vertically. The inlet piping should be short and direct, without pockets. Ensure nameplate details are visible. Outlet piping should be free, draining away from the valve to prevent liquid accumulation. Provide proper supports for valve and piping considering reaction forces. Relief valves are not an end user serviceable device. They must be worked on by a certified VR shop. They should be tested annually at minimum to verify set pressure and that the valve is free to operate. Choosing the Right Safety Relief Valve Manufacturer Selecting the right safety relief valve manufacturer is crucial for system performance and safety. What to Look for in a Reliable Relief Valve Supplier Quality Certifications and Industry Reputation Choose a supplier who values meeting the highest industry standard, and with proven expertise in industry-specific valves. Ensure they meet quality standards and certification like ISO-9001 and ASME certification, showcasing compliance and a commitment to quality management and excellence. A strong reputation backed by customer reviews and industry recognition is essential. Technical Support Availability Since relief valves are critical to the safety of oil and gas production facilities, assurance of prompt and reliable technical support from suppliers is very important. Conclusion Selecting the right relief valve involves assessing key factors like operating pressure, material compatibility and selecting a manufacturer who is reputable and values the highest quality standards. Choosing a high quality relief valve for your oil and gas system is vital to the integrity of your system, and the safety and protection of your environment and personnel. Properly specified, installed, and maintained relief valves ensure safety, operational integrity, and compliance with stringent industry standards. Protect your people, your environment, and your infrastructure with BMD’s trusted safety relief valves. Contact BMD today for expert guidance and top-tier relief valve solutions for your oil and gas system.

March 3, 2025

At Beaumont Manufacturing and Distribution (BMD), innovation and quality are at the core of everything we do. By achieving certifications like ISO 9001:2015, ISO 15848-1:2015, and compliance with Quad O regulations, we demonstrate our commitment to delivering high-performing, environmentally sustainable solutions for the oil and gas industry. These standards not only validate the reliability and durability of our products but also reinforce our mission to minimize fugitive emissions, enhance operational efficiency, and align with the highest industry benchmarks for quality and environmental responsibility. Let’s explore each of these certifications and standards. ISO 9001:2015 – Quality Management System ISO 9001:2015 is an internationally recognized standard for Quality Management Systems (QMS). It provides a framework for organizations to ensure consistent quality in their products or services while improving customer satisfaction and operational efficiency. Businesses that are ISO 9001 certified are audited yearly to keep in good standing to hold this distinguished certification. The standard focuses on principles such as: Customer Focus: Understanding and meeting customer needs and striving to exceed expectations. Leadership: Establishing a clear vision and creating an environment that encourages team involvement. Engagement of People: Ensuring everyone in the organization is engaged, competent, and motivated to contribute to its success. Process Approach: Managing activities and resources as processes to achieve consistent and predictable outcomes. Improvement: Continually improving processes, products, and services. Evidence-Based Decision Making: Using data and analysis to make informed decisions. Relationship Management: Fostering strong relationships with suppliers, customers, and stakeholders. Organizations certified under ISO 9001:2015 demonstrate their ability to consistently deliver high-quality products or services while maintaining a commitment to continual improvement. It applies to businesses of all sizes and industries. BMD ISO 9001:2015 Certification Beaumont Manufacturing and Distribution (BMD), is certified by ISO 9001:2015, the international gold standard for Quality Management Systems. This certification reflects our rigorous processes for designing, manufacturing, and distributing valves and controls, ensuring customers receive reliable, high-quality products. Through continuous improvements, we deliver superior performance that meets and exceeds customer expectations, while adhering to strict industry requirements. ISO 15848-1:2015 – Fugitive Emissions Standards Fugitive emissions are a growing concern in the oil and gas industry due to their environmental and regulatory implications. ISO 15848-1:2015 is an internationally recognized standard that defines the measurement, testing, and qualification procedures for fugitive emissions from industrial valves. Fugitive emissions refer to the unintended release of gases or liquids, often harmful, from valves and other equipment into the environment. This standard focuses on reducing these emissions to improve environmental safety and meet strict regulatory requirements. Key Aspects of ISO 15848-1:2015: Tightness Classes: Specifies leakage limits (e.g., parts per million by volume or ppmv) based on the level of emissions allowed. The tightest class (e.g., AM) permits less than 50 ppmv leakage. Cycle Classes: Defines how many operational cycles (e.g., open/close) a valve must endure while maintaining its tightness. Classes range from: CC1: 20,000 cycles CC2: 60,000 cycles CC3: 100,000 cycles Testing Requirements: Valves must be tested in third-party laboratories under controlled conditions to ensure they meet the leakage and durability requirements. Focus on Environmental Sustainability: Supports industries in complying with stricter regulations by minimizing harmful emissions, such as greenhouse gases, which contribute to climate change. Importance in Industry: Environmental Compliance: Helps companies meet local and international environmental regulations. Operational Efficiency: Reduces maintenance costs and downtime by using robust, high-quality valve packing systems. Sustainability Goals: Supports initiatives to lower emissions and reduce the carbon footprint of industrial operations. BMD ISO 15848-1-certified At BMD, valves equipped with ISO 15848-1-certified fugitive emissions packing ensure top performance while aligning with environmental standards, providing durability, reliability, and compliance with global emissions regulations. View all BMD control valves here. More About Innovative Packing Solutions for Reduced Emissions BMD’s patent-pending packing design uses alternating layers of engineered composite materials and live-loaded spring mechanisms to create a durable, leak-tight seal. Certified to stringent standards such as ISO 15848-1, this solution provides long cycle life, reduced maintenance, and significant reductions in greenhouse gas emissions, supporting sustainability goals while lowering operational costs BMD’s patented packing technology offers unmatched performance and reliability. Key features include: High Cycle Life: BMD valves are CC3 rated, or tested to over 100,000 cycles. Our packing ensures longevity and reduced maintenance costs. Tightest Leak Class: Achieving the AM class, with leakage below 50 ppmv, minimizes emissions and meets environmental regulations, such as Quad O standards. Spring-Loaded Design: With components like live load springs and spherical washers, our packing maintains consistent sealing performance over time. Extensive Testing for Proven Results BMD’s products undergo rigorous third-party testing to ensure compliance with ISO 15848-1 standards. These tests validate the durability and performance of our packing materials, allowing us to confidently implement them across our entire control valve product line. This commitment to quality testing not only ensures product reliability but also helps our customers reduce costs associated with frequent maintenance and emissions monitoring. Environmental and Financial Benefits By preventing fugitive emissions, BMD’s ISO 15848-certified packing reduces environmental impact while aligning with industry sustainability goals. Customers also benefit from cost savings by avoiding penalties related to emissions regulations and minimizing maintenance downtime. Under the new Quad O standard monthly LDAR inspections are needed if more than 2% of valves and devices are leaking over 500 ppm. This is reduced to quarterly LDAR if less than 1% of devices are leaking, with requirements decreasing as the number of leaking devices declines. Upgrading to superior packing to prevent leaks can save considerable time and expense. Conclusion To summarize these certifications: ISO 9001:2015 focuses on quality management systems, ensuring that BMD’s products are designed, manufactured, and distributed consistently to meet or exceed customer expectations. ISO 15848-1:2015 addresses fugitive emissions, certifying that BMD’s valve packing solutions effectively prevent leaks, comply with global environmental standards, and maintain a tight seal even under demanding operational cycles. Quad O regulations (New Source Performance Standards) are specific to oil and gas operations, targeting reductions in methane emissions through strict leak detection and repair (LDAR) protocols. Together, these certifications establish BMD as a trusted partner for safe, sustainable, and efficient solutions in oil and gas operations.

November 29, 2024

The natural gas industry plays a critical role in today’s energy landscape, offering a cleaner, more efficient alternative to traditional fossil fuels like coal and diesel fuel. In recent years, this alternative fuel source has gained traction across various sectors, from power generation to transportation. However, the efficient movement of natural gas relies heavily on natural gas compression—a process that ensures this essential fuel travels long distances effectively. Without compression, the transportation of natural gas would face significant challenges, including higher costs and increased environmental impact. The Shift to Natural Gas Engines: A Growing Trend The transition from diesel engines to natural gas engines marks a significant shift in mass transit and industrial applications. Natural gas vehicles are becoming increasingly common, offering lower greenhouse gas emissions and reduced particulate matter compared to traditional fuel sources. Additionally, renewable natural gas and compressed natural gas (CNG) have paved the way for new advancements in vehicle fuel technology. Natural gas compression plays a vital role in this movement. By increasing the gas pressure at compressor stations, natural gas can be stored in smaller volumes, transported in CNG tanks, or delivered efficiently to fast-fill stations and time-fill stations for use in various industries. This transition not only supports sustainability but also enables greater efficiency in fuel transportation and storage. The Mechanics of Natural Gas Compression and Transport Natural gas compressors are essential for the movement of natural gas through pipelines and other transport systems. These units operate by increasing the pressure of natural gas to make it easier to store and move. At a natural gas compressor station, the gas undergoes a compression process to achieve the necessary pressure for efficient transportation. There are various types of compressors, including rotary screw compressors, reciprocating compressors, and centrifugal compressors, each designed for specific applications. For instance, positive displacement compressors are often used in smaller-scale operations, while larger compressors manage the higher pressures required for industrial uses. Compressor stations are strategically located along pipeline routes or at wellheads to ensure the smooth transportation of natural gas. These stations reduce the gas volume, allowing it to be stored in high-pressure cylinders or transported in liquid form (LNG). This compression process is crucial for overcoming long distances and ensuring natural gas reaches its destination without significant loss of quality or efficiency. Understanding Natural Gas Compression Services Natural gas compression services are vital for preparing natural gas for use in various applications. Raw natural gas extracted from the ground often contains impurities like carbon dioxide, water vapor, and particulate matter. Before it can be used as a fuel source, it must undergo a series of processes to meet quality standards. The first stage of compression often involves removing contaminants and increasing the gas pressure to standard atmospheric pressure. In some cases, the gas undergoes further distillation, separating it into components like natural gas liquids, which are used in industrial and commercial applications. By utilizing advanced compression stages, including diaphragm compressors and rotary screw compressors, the natural gas industry achieves higher efficiency in preparing gas for diverse applications. These processes are not just about making gas usable; they also contribute to reducing maintenance costs, improving environmental impact, and enabling the use of CNG infrastructure, such as CNG stations and high-pressure storage tanks. The Future of Natural Gas Compression As the demand for alternative fuel sources grows, natural gas compression remains at the forefront of innovation. Advancements in compressor mechanics, including the use of composite materials and improved compression ratios, are enabling greater efficiency and reduced environmental impact. Natural gas compression packages are becoming more sophisticated, catering to specific applications with features like suction control valves and electric motors for enhanced performance. The shift toward natural gas as a primary fuel source is driven by its versatility and lower greenhouse gas emissions . From powering gas engines to supporting renewable energy initiatives, the transportation of natural gas through efficient compression systems is essential for meeting the energy demands of the future. Whether used in commercial applications, power generation, or industrial processes, natural gas compression services ensure the movement of natural gas continues to be a reliable and sustainable solution. Efficiency and Environmental Impact of Natural Gas with Beaumont Manufacturing and Distribution Beaumont Manufacturing and Distribution (BMD) is leading the charge in making natural gas compression a more sustainable and environmentally friendly process. By focusing on advanced technology and eco-conscious practices, BMD helps reduce the environmental impact of natural gas transportation while enhancing efficiency and cutting costs. Comparison of Natural Gas to Diesel Fuel: A Cleaner Alternative Natural gas is already a cleaner fuel source compared to traditional fossil fuels like diesel fuel. With the rise of renewable natural gas, the benefits are even more pronounced. Unlike diesel, natural gas produces significantly fewer greenhouse gas emissions and particulate matter, making it a better choice for the environment. This cleaner-burning fuel is essential in reducing the environmental impact of mass transit, industrial uses, and natural gas vehicles. BMD ensures that the natural gas compression process aligns with these environmental benefits. By integrating compressors that use the same gas they compress as fuel, BMD eliminates the need for external fuel sources like diesel, further reducing emissions and simplifying operations. The Role of High-Efficiency Compressors in Sustainability BMD’s compressors are designed with sustainability and efficiency in mind. These high-efficiency compressors contribute to lower emissions, longer operational lifespans, and reduced maintenance costs. Automated Operations for Greater Efficiency BMD’s compressors are fully automated, using advanced computer systems to optimize performance. Automation minimizes energy waste during the compression process, ensuring the gas pressure is achieved with the least energy expenditure. Zero-Emissions Packing and Vent-Free Valves To comply with stringent environmental standards like 0000 B/C compliance, BMD offers zero-emissions packing and vent-free valves . These features capture emissions during the compression process, reducing the release of harmful greenhouse gases and maintaining compliance with regulatory requirements. Durable Components for Reduced Maintenance Longer-lasting valves and innovative materials ensure that BMD’s compressors require less frequent maintenance. This not only lowers costs but also reduces downtime, ensuring consistent efficiency throughout the system. Energy Efficiency: Using Natural Gas to Compress Natural Gas One of the most innovative aspects of BMD’s compression systems is the ability to use natural gas as both the fuel and the compressed product. This self-sustaining process eliminates the need for external energy sources like diesel tanks, cutting down on logistical costs and emissions. Wildly Efficient Compression A portion of the natural gas extracted is burned by the engine to compress the remaining gas. This closed-loop system enhances energy efficiency, as the compressors essentially run on the same fuel they process. Cost-Effective Operations By using the natural gas already in the system, BMD compressors eliminate the need to transport additional fuel. This results in lower maintenance costs and reduced carbon emissions, aligning with the push toward alternative fuel sources. Beaumont Manufacturing and Distribution’s commitment to sustainability extends across its operations. By employing innovative compressor mechanics and focusing on compliance with environmental standards, BMD ensures that natural gas remains a cleaner and more efficient fuel source for various applications. Our high-pressure compressors, automated processes, and eco-friendly features set us apart as leaders in the natural gas industry, making the transportation of CNG and LNG as environmentally friendly as possible. Conclusion The mechanics of natural gas compressors and the services they provide are critical to the movement of natural gas. By enabling the transportation of CNG and LNG, these systems support the natural gas industry’s efforts to deliver a cleaner, more efficient fuel source. As advancements continue, the role of natural gas compression in various industries will only grow, ensuring this vital resource meets the world’s energy needs.